Blog | Reading Time 3 minutes

Leveraging Enzymes and Process Aids to Improve Brewing Efficiency

There is no single silver bullet for a brewery to reduce their environmental impact. Rather, it is the optimization of each of the many steps in the brewing process that leads to a greater cumulative effect. Fortunately, optimization efforts usually lead to cost savings as well , giving everyone an added incentive to increase efficiency and reduce waste.

Enzymes and process aids are invaluable tools for optimizing the brewing process. For example, enzymes and process aids can reduce fermentation and maturation time, improve mash extract and lautering times, increase yields, and extend product shelf-life. While these tools are commonly used in larger breweries that are focused on efficiency, it is less common for enzymes and process aids to be used in smaller, craft breweries. This is changing as customers demand greater environmental responsibility, and brewers are under increasing pressure to cut costs and get an edge on the competition.

The Role of Enzymes and Process Aids in Brewery Efficiency and Environmental Impact

Fermentation and Maturation Time – There are many ways that a brewer can improve the efficiency of the brewing process. Faster tank turnarounds can help you get more volume out of your brewery without purchasing new fermenters, which require energy and resources to manufacture and ship. Nutrients can help speed up fermentations and prevent off-flavors during fermentation, thereby reducing maturation time and lowering the energy required for cooling the beer. Using an acetolactate decarboxylase enzyme (ALDC) will break down diacetyl precursors and eliminate the need for a diacetyl rest. Maturation can also be shortened by using finings or proteases to speed up clarification and improve filtration.

Malt – Enzymes can help to improve mash efficiency, which allows for the total grain bill to be reduced. Glucosidic enzymes such as fungal α-amylase or glucoamylase will increase the extraction of fermentable sugars from the malt. Glucanase enzymes will improve lautering and extract. Protease enzymes can increase the FAN levels when using low FAN adjuncts. These enzymes all support the use of higher levels of adjuncts, and local or organic malts that tend to have lower or inconsistent levels of enzymes. The malting process is energy and water intensive, so replacing some malt with adjuncts requires fewer resources.

Hops – Antifoams can be used in the kettle or fermenter to reduce losses due to boil-overs or fermenter blow-offs. Antifoams can also increase hop utilization since less α-acids are lost in the foam, so hop rates can be reduced. β-Glucosidase enzymes can promote biotransformation and improve total hop aroma without increasing hop rates.

Yeast – Zinc is especially important, and yeast-derived sources of zinc such as Servomyces™ are more bio-available to yeast during repitching.

Product Yield – Process aids can increase the total product yield per brew. Using kettle finings and beer finings will increase the yield of wort and beer, respectively. The usable kettle and fermenter capacity can be increased by using antifoams to reduce the amount of headspace required.

Shelf life – Increased product stability can reduce wastage of finished product and packaging. Shelf life can be improved by using antioxidants to prevent staling. Proline-specific proteases can reduce colloidal haze and increase product shelf life.

Other consumables – Using finings can extend filter life and reduce the need to use excess water to backflush. Antifoam will reduce the amount of chemicals and water required to clean a tank.

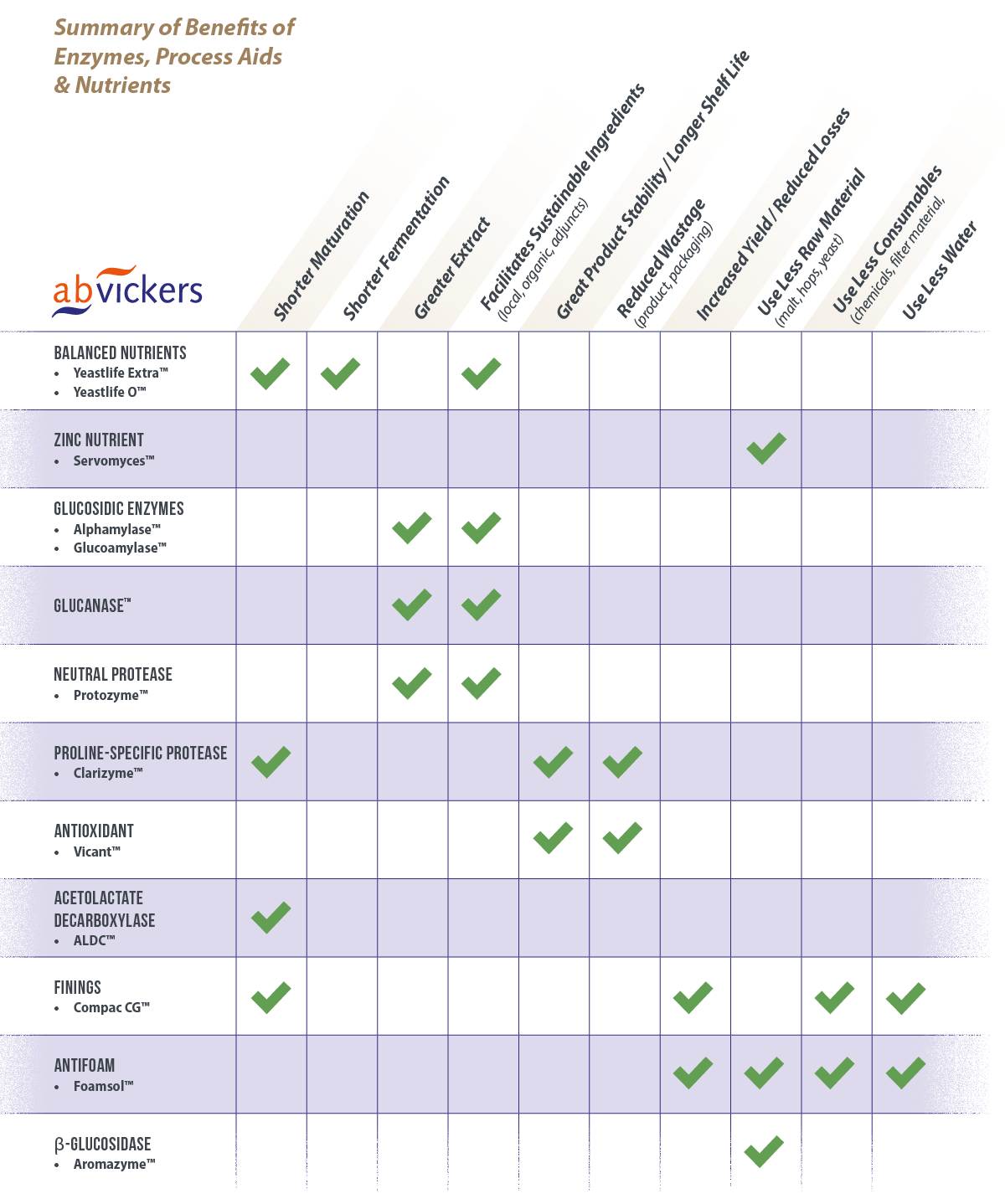

The applications are seemingly endless for enzymes and process aids to increase efficiency, reduce environmental impact, and lower costs. These products are widely available and generally do not require additional equipment to use. We have included a quick-reference guide to summarize which products can be used to achieve different outcomes. For any additional information about enzymes or process aids, contact us at brewing@lallemand.com

Published Aug 9, 2024 | Updated Sep 12, 2024