Blog | Reading Time 3 minutes

Energy Reduction in Fermentation and Maturation

What role does yeast play in energy use? Both suppliers and brewers are increasingly recognizing the importance of addressing sustainability concerns throughout the brewing process. From sourcing ingredients to packaging, every aspect of brewing plays a role in its environmental footprint. There is a growing need to find innovative solutions to minimize energy consumption and reduce waste. As yeast producers, we are exploring ways that our strains can be used to help breweries reduce their environmental impact. We identified LalBrew Voss™ and LalBrew NovaLager™ as having potential to reduce the energy required for cooling due to their ability to ferment at warmer temperatures. But how much energy could you save?

Putting it to the test

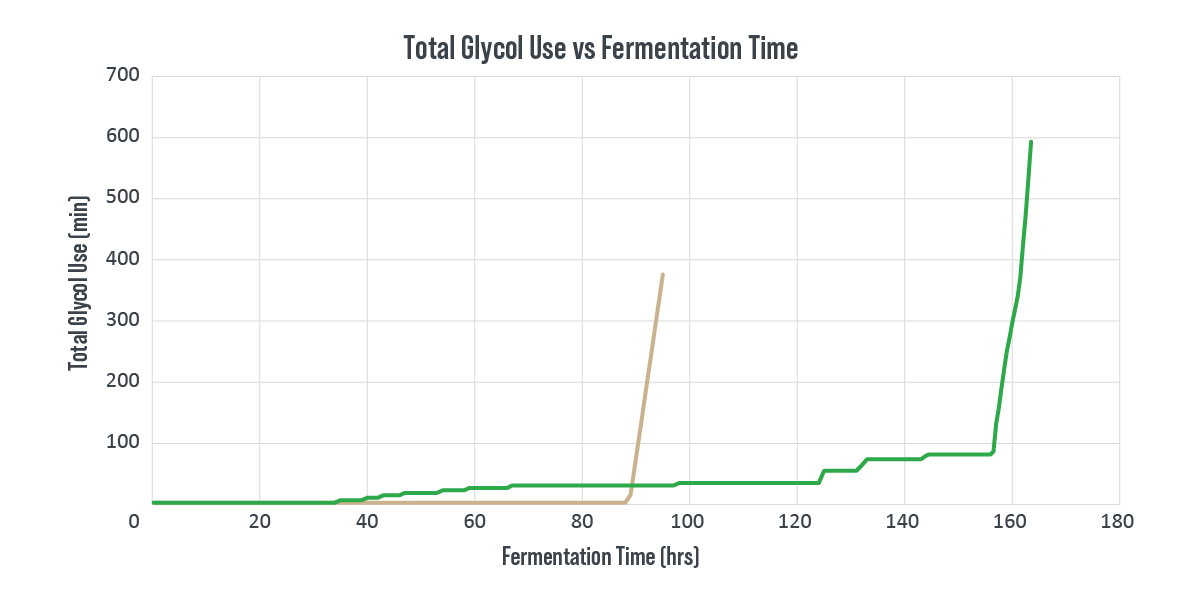

We conducted a series of pilot fermentations to measure how much energy could be saved by fermenting at warmer temperatures. LalBrew Voss™ fermented at 35°C was compared to LalBrew Nottingham™ fermented at 20°C, and LalBrew NovaLager™ fermented at 20°C was compared with LalBrew Diamond™ fermented at 12°C. Relative energy consumption was monitored by tracking the on/off time of compressors or glycol chillers during fermentation and cold crash (Fig 1).

The experiments yielded valuable insights into the relationship between yeast strains and energy efficiency. While there was a reduction in energy use with the warmer fermentation strains, the actual energy savings were lower than initially anticipated. In fact, the energy consumption during the chilling phase of maturation emerged as a more significant factor than fermentation temperature. The total cooling time (glycol or compressor running) during these fermentations was only about 12 hours. Therefore, reducing your cold maturation time by as little as a day will lower your energy consumption more significantly than fermenting at warmer temperatures. Our experiments show that the energy savings from even a small reduction in cold maturation time will likely be greater than energy savings due to warmer fermentation. Be wary of exaggerated claims from any supplier.

Energy reduction through shorter maturation

While fermentation temperature may not be a significant factor, yeast still has a role to play in reducing energy use by reducing maturation times.

Figure 1: Total fermenter glycol chilling time when using (A) LalBrew Voss™ and (B) LalBrew Nottingham™.

Here are some practical tips for reducing energy consumption during maturation:

- Choose non-H2S strains such as LalBrew NovaLager™ or LalBrew Farmhouse™

- Choose strains that do not require a diacetyl rest such as LalBrew NovaLager™

- Choose high-flocculation strains, or alternatively, brew hazy styles that don’t require clarification

- Brew short maturation styles such as wheat beers and IPA

- Monitor VDK levels closely to ensure minimal maturation time without compromising beer quality

- Use enzymes such as ALDC (diacetyl reduction) or proteases such as Clarizyme™ (reduces chill haze)

- Use finings (Vicfine™, Protofine™, or Protosol™) for faster clarification

Improved efficiency throughout the brewing process

While energy savings during fermentation alone may not be as substantial as once thought, brewers can improve efficiency by addressing all aspects of the brewing process. Install heat recovery systems. Upgrade to more energy-efficient equipment. Use antifoam agents (Foamsol™) to optimize cleaning processes and minimize chemical usage. Adopt precision fermentation management techniques.

These are just a few initiatives that, collectively, contribute to enhancing overall efficiency within the brewing process. As an industry, embracing innovation and collaboration will be paramount in driving towards a more environmentally friendly future for brewing.

Published Jul 29, 2024 | Updated Sep 12, 2024