Compac CG™

Do you need an easy solution for improving filtration and haze stability? Is your whirlpool trub not compact and contributing to haze in your beer? See what Compac CG™ can do for you.

Compac CG™ is a semi-refined, granulated form of the seaweed species Eucheuma cottonii. The species Eucheuma cottonii is rich in the kappa isomer of carrageenan.

Added 5 minutes before the end of kettle boil or upon whirlpool transfer. When added to boiling wort kappa carrageenan reacts with soluble proteins, notably the proline-rich fraction which can cause haze. Once the wort is cooled, the carrageenan-protein complex becomes unstable and precipitates out of solution. The resulting clear wort produces a beer with enhanced processing characteristics.

Benefits

- Improved hot break compaction in the whirlpool leading to higher wort extraction

- High cold break precipitation resulting in a clearer wort

- Reduced final haze with enhanced colloidal stability

Video

More information

Compac CG™: Transforming Wort through Effective Protein Removal

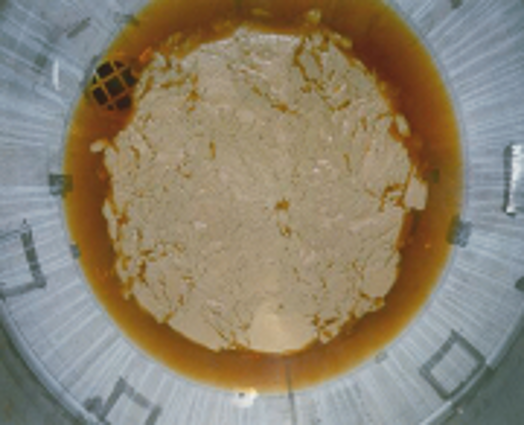

Hot Trub Compaction

In the wort boiling process, Compac CG™ is added to the wort, where it forms a random coil and react strongly with soluble proteins. Once cooled, the combined particles (protein Compac CG™ complex) become heavier and sediment out of the wort.

Photo 1: Wort without addition of Compac CG™ Photo 2: Wort with addition of Compac CG™

In Photo 1, without the addition of Compac CG™, the trub cone is less compact. A stratified trub cone has an increased risk of coagulated protein polyphenol complexes transferring over into FV. This can cause ‘off’ flavours, sluggish fermentation, increased haze and poor filterability downstream.

In Photo 2, the wort treated with Compac CG™ has formed a compact trub cone. The protein polyphenol complexes stay bound allowing for an increased volume of wort to be transferred into FV. This can improve brewhouse efficiency by increasing fermentable wort volume, without the risk of high levels of protein and polyphenol loading.

Cold Trub Compaction

Photo 3: Optimized Clarity with Compac CG™

In Photo 3 , the clarity of the wort is improved by Compac CG™ addition. Sample 1 contains no addition of Compac CG™, while sample 3 shows improved wort clarity resulting from cold break precipitation at an optimal dose rate of Compac CG™.

FAQ

- Compac CG™ gives brewers better hot break compaction meaning more extraction of wort (less waste)

- Improves cold break compaction leading to clearer wort which gives longer filter runs improving your usage of your filter materials

- Improves turnaround time so beer is processed faster

- Improves final haze and colloidal stability as the problematic sensitive proteins which can bind to polyphenols from hop products are reduced

By weighing the optimal amount the adding into the wort kettle 5-10mins before the end of wort boil. Alternatively into the whirlpool as it is being filler. If using a dosing system, program to dose into the wort during the final stage of the boil.

Copper finings are an easy way to make a big improvement in your beer clarity and filterability. To check you are using the right amount you can do two things:

- Carry out an optimization-check out our optimization guide (see our optimization document or video above) this ensures correct additions even if there are raw materials or process changes.

- Take a cold wort sample at cast, post heat exchanger and allow it to settle overnight. Cloudy wort indicates you are not adding enough. Bright wort with high sediment levels ( over 5%) means you are adding too much – optimize.

Compac CG™ is a Pure Granular form which means the active ingredients are at the highest concentration and lower dose rates are required to achieve the best results. Compac CG™ Tablets are useful for smaller breweries to allow easy consistent addition without having to measure each time. The tablets are mixed with a dispersant to allow for better mixing.

Powder, is for automatic dosing systems.

Store Compac CG™ in a dry location at room temperature.

With regards to Finings, it is common to combine copper fining use with cellar finings, such as silica sol or isinglass, which are added post fermentation and reduce haze contributed by yeast during fermentation.

Kettle and copper finings are the same thing and refer to the addition point which is in the brewhouse on the hot side. Irish moss is another type of kettle fining from the Chrondrus Chrispus species of seaweed. It has a lower concentration of the active ingredient kappa carrageenan than in Euchema cottonii which is used for Compac CG™ . It is therefore less effective at removing the haze forming proteins.

For more information about Compac CG™, please contact our customer sales manager for AB Vickers products, Sarah Young, at syoung@lallemand.com. Our experts are ready to assist you with any questions you may have.